The pulse industry in Western Canada is steadily gaining momentum. As the International Year of Pulses winds down, the awareness raised and relationships forged during 2016 will continue. Industry, research and policy leaders are using that momentum to build the Protein Highway, a US-Canada cooperative initiative.

The pulse industry in Western Canada is steadily gaining momentum. As the International Year of Pulses winds down, the awareness raised and relationships forged during 2016 will continue. Industry, research and policy leaders are using that momentum to build the Protein Highway, a US-Canada cooperative initiative.

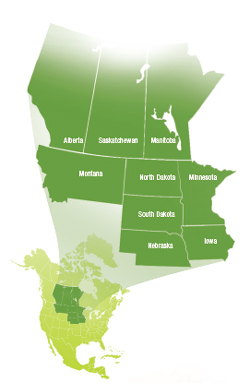

The North American Midwest has long been considered the world’s “bread basket.” Ag-West Bio’s president and CEO Wilf Keller says that an increased global population, along with rising incomes, will lead to a greater demand for protein. With a huge capacity for growing plant-based proteins, this region is poised to become the world’s “protein basket.”

“Across Western Canada and the northern US, there are well over 100 million acres of land, with fewer than 10 million people living on it. That is an undeniably rich resource,” he says.

In the spring of 2015, the Consulate General of Canada in Minneapolis organized a meeting (in conjunction with a visit by the Governor General of Canada) with Canadian and US stakeholders, to discuss opportunities for the northern United States and Canadian Prairie provinces to work together on agriculture and food initiatives. The working group, comprising representatives from industry, academia, government and investor organizations, explored the need to connect producers, researchers, investors and entrepreneurs to expand the industry, diversify and create value-added products. They naturally arrived at the importance of plant-based proteins.

A whitepaper for creating a regional approach to enable innovative agricultural technology solutions from plant proteins was published in February, 2016. An asset map of research institutions and current projects and expertise is also being created.

Regional assets

The natural resources of the Protein Highway region are the starting point for the initiative. The area included in the Protein Highway has the ideal climate, industrial infrastructure, and breeding and processing research clusters to support it.

Keller says, “There is so much growth in dryland pulses in Canada. We are producing a great variety of peas, lentils and beans. Another major crop, canola, contains excellent protein in the meal, available after the oil is extracted. Soybeans are also grown extensively in the US and shorter season varieties are being grown in Canada.”

Pulse acreage in Canada is increasing: peas are at more than four million acres and growing, and lentils are at nearly six million acres. Carl Potts, Executive Director of the Saskatchewan Pulse Growers (SPG), says “Saskatchewan is the largest producer and exporter of lentils in the world. We export lentils as a staple food to over 100 countries.”

An important pillar of SPG’s strategic plan is to expand the market of pulse crops. They have a firm market share in exporting pulses as whole foods. But there is also great opportunity in developing markets for pulse-based ingredients in North America and Europe. The health benefits of pulses are just being discovered.

Breeding programs at the University of Saskatchewan’s (U of S) Crop Development Centre have introduced dozens of specialty varieties to the Prairies. Bert Vandenberg, Saskatchewan Pulse Growers Industrial Research Chair in Genetic Improvement of Lentils, has introduced more than 30 lentil varieties in 10 market classes over the last 20 years. Ongoing projects aim to introduce more genetic variety into lentils, to create more adaptive opportunities.

Research on value-added products relies on existing synergies in Saskatchewan’s research cluster. Shannon Hood-Niefer, VP Innovation and Technology at the Saskatchewan Food Industry Development Centre (Food Centre) identifies three key players in the Saskatchewan research cluster: the Food Centre, the U of S Food Science faculty and POS Bio-Sciences. “These three organizations link the university research skillset, extraction and fractionation skillset at POS, and ingredient evaluation of the Food Centre,” she says. Other universities within the Protein Highway region have similar food research capacity.

Meeting global needs

Building networks and clusters of research, people and expertise will help create demand for pulse crops over time, to diversify markets and return more value to farmers. Globally, there is an increasing demand for protein in multiple markets:

• Growing populations in India, Pakistan and Southeast Asia, where pulses are a traditional staple, mean increased demand.

• As these countries become more affluent, they also expect to consume more animal protein. Plant proteins, such as peas, make high quality animal feeds that help convert plant proteins to animal proteins efficiently.

• In North America and Europe, there is increased demand for high protein specialty food products. Pulses can be processed into fractions of starch and protein; they can be blended with other foods; and even create vegetable-based meat replacements.

• The growing aquaculture industry will be looking for high-protein vegetable-based fish food.

• Protein crops can also create high quality pet foods as alternatives to those made from meat by-products.

“There’s no doubt that there’s strong demand for plant protein other than soybean or wheat,” says Bob Tyler, Associate Dean of the College of Agriculture and Bioresources at the U of S. “Our philosophy is that anything you can do with soy protein, you can do with pulse proteins. Currently, pea protein processors can’t satisfy the demand.”

Connecting research, entrepreneurs, and investment

The technology and regional assets are in place, but there are challenges.

In this novel, cooperative approach to sharing expertise, one challenge will be to move beyond traditional resistance, to cooperating with the ‘competition’. With respect to binational competition, Potts says we’ve been working beyond Saskatchewan and Canadian boundaries.“We’re already working with the USA Dry Pea and Lentil Council to increase awareness of pulses in North America.”

Mike Nickerson, Ministry of Agriculture Strategic Research Chair, and an Associate Professor in the U of S Department of Food and Bioproduct Sciences, can see the benefits for public researchers to connect with other expertise across the Protein Highway region. “We can work synergistically to tackle bigger issues or bigger problems as a whole. From a research perspective there are huge opportunities.” He believes the industry is ready to capitalize on an increase in demand. “Even though the trading companies compete with each other for business and market share, if we can increase the overall size of the pie, then market demand is larger for everyone,” he says.

Tyler agrees. “We have the technology to do whatever we put our minds to. It’s about making it economically viable. The challenges are not technical knowledge—it’s making money, marketing, and the size of the investment versus the pressure from competition.”

The success of the Protein Highway rests in undoing some past habits. Cooperating with competition is one such adjustment; shifting from our commodity and export economy focus is another. Tyler says we will likely be commodity based in Western Canada for a long time. “But that doesn’t mean we shouldn’t add value where we can.”

Vandenberg says more than just bulk exports will be required to support the Protein Highway. “It took Canada a long time to begin crushing our own canola, and we’re at 50% today. It’s the same with pulses. You have to have a healthy local dehulling industry before you can create value-added products in any great numbers.”

Next steps

The first vehicles to travel the Protein Highway will be ideas and information. The consortium is creating a portal to share among organizations, with branding and website development underway. The Protein Highway was officially launched at ABIC 2016 in Fargo, North Dakota in September.

What the Protein Highway becomes remains to be seen. Keller says, “It will grow organically, and it will grow as people see a need to work together and respond to opportunities to develop new products. A binational initiative like this could become a model to other sectors trying to do something similar.”

Originally published in Ag-West Bio’s 2016 Annual Report. Photo: istock photos184099878